What Size Air Compressor Do You Need?

13th Apr 2021

Between understanding PSI, CFM and tank size, finding the right size air compressor for your air tools is not always straight forward.

To simplify the process, we’ve created this guide.

Here, we’ll give you everything you need to make sure you choose the right size air compressor for your application, and recommend some of our best air compressors up to the task.

What Size Air Compressor Do I Need?

10-20 CFM Rating

Air compressors with lower CFM ratings between 10-20 are ideal for less demanding or intermittent use tools like nail guns, air grinders and sanders. They’re also sufficient for tire inflation.

Our Top Pick – 16 CFM Piston Air Compressor

This 4HP 16CFM piston air compressor is well-suited to variable air demand in low to medium volumes. It features a forged steel crankshaft and efficient air filters to ensure a clean intake of air and a long service life.

50+ CFM Rating

Air compressors with CFM ratings of 50 or above are well-suited for industrial applications and more demanding tools. They’ll comfortably power jackhammers, larger impact wrenches and rock drills.

Our Top Pick – 92.1 CFM Screw Compressor

Atlas Copco’s 25HP 92.1CFM rotary screw compressor is a powerful, reliable air compressor ideal for small to medium sized industries. It comes with a built-in refrigerant air dryer that cools the compressed air and removes any moisture, preventing rust in your compressed air piping.

4 Steps To Choose The Right Size Air Compressor

1. Understand HP, PSI & CFM

When choosing the best air compressor for the job, there are three key things you need to understand:

- HP: A compressors horsepower (HP) rating indicates the power output of the engine or motor. The higher the HP rating, the greater the air pressure, measured in PSI.

- PSI: PSI (or pounds per square inch) is a measurement of the force of air coming out of the compressor. High PSI means the compressor can store more air in the tank, allowing you to operate tools for longer periods.

- CFM: CFM (or cubic feet per minute) is the volume of air the compressor delivers at specific PSI levels. A compressor with a high CFM rating delivers more air and is well-suited to heavier applications like operating air wrenches.

2. Check The Requirements Of Your Tools

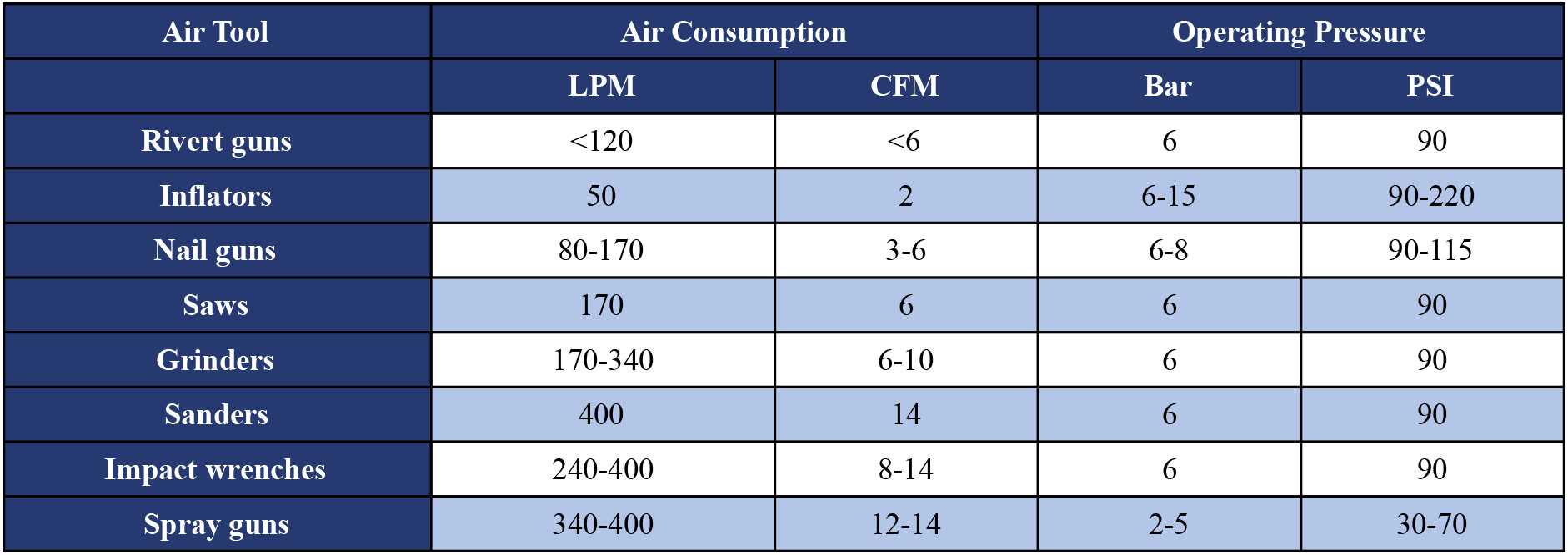

Air tools have requirements for air consumption, which is typically measured in LPM (litres per minute) or CFM. They also have an operational pressure requirement, normally measured in bars (b) or PSI.

So, to determine the right size air compressor for your air tools, identify the tool that requires the highest CFM and PSI to function. Then, as a rule of thumb, select a compressor that offers a CFM rating roughly 20% higher than this.

For example, if you have a spray paint gun that requires 5 CFM at 90 PSI, look for a compressor that delivers at least 7.5 CFM at 90 PSI.

Here’s a guide on the approximate air consumption and operating pressures of common air tools:

Note: If you plan to run multiple tools simultaneously, combine their total CFM rating to determine what size air compressor you need.

3. Determine Your Tank Size

The volume of the reservoir tank determines how long you’ll be able to use your compressor between cycles.

Compressors with smaller tanks, around 10-20L, are ideal for most projects, like operating nail guns and wrenches. On the other hand, tools that require a constant flow of air, such as grinders, paint guns and sand blasters, need a compressor with a larger tank.

A simple way to determine what tank size you require is to multiply your tools required CFM by 6. For example, if your impact wrench requires 8 CFM (8x6=48), you’ll need at least a 48L compressor tank to support it.

4. Note The CFM Duty Cycle

Duty cycle is the amount of time the compressor can run before it needs to stop and pressurise new air. It determines how often the compressor will be cycling on and off while working.

For example, if an air compressor’s total cycle time were 10 minutes and it ran for 6 minutes during that time, it would equate to a 60% duty cycle.

For intermittent tools like nail guns, a compressor with a 50-60% duty cycle will be sufficient. However, for continuous use tools like sanders and paint sprayers, look for a compressor with a 100% duty cycle. This means the compressor will operate continuously at its optimum CFM and PSI rating without needing to stop regularly.

The tool enables pressure to apply and cut hard materials, loosen tight bolts and other complex tasks otherwise impossible to complete. It is important to have researched and understood the air pressure requirements of a tool or application to narrow the compressor's size.

Too much pressure on your air tools can result in costly mistakes, but there are further-reaching consequences in addition to this, like equipment failure, repair costs and health/safety risks for those working around the compressor.

Get The Right Advice, Contact Us Today

With years of experience, you can rely on Blue Diamond Machinery to provide the right advice and an air compressor to meet your unique requirements.

For more information on the best model to suit your requirements, contact us today or speak to one of our expert team on 1300 998 647.